Upgrade Data Collection with instant Reporting for Effective Fleet Maintenance Decision

UTM Reporting: The simplest and most effective tool for completing your ultrasonic inspections

UTM Reporting: The simplest and most effective tool for completing your ultrasonic inspections

Fill the project information & upload blueprints

Split the inspection into hull items to be inspected

Locate thickness measurements on vessel blueprints

Generate a gauging report within seconds

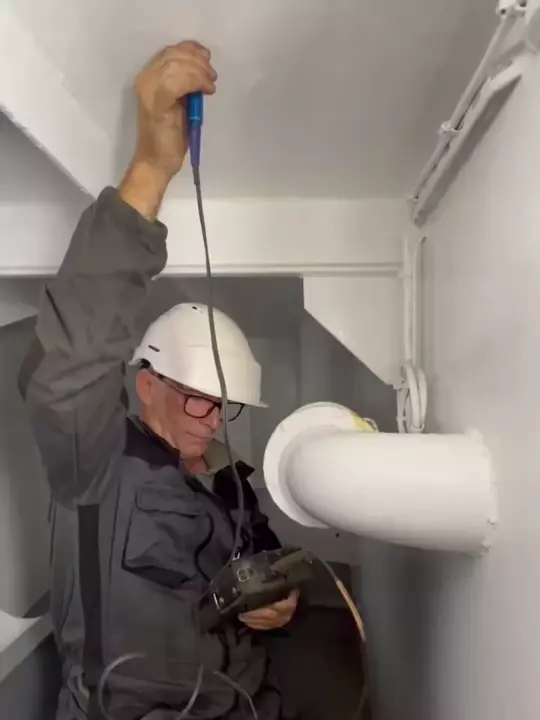

Efficient data collection

Streamline thickness data collection and easily keep track of corrosion and defects

-

Standardize your survey tool to simplify collection and storage of vessel condition data

-

Locate easily the corrosion with digital thickness measurement markers

-

Capture and locate accurately defects on vessel plans with a note and a picture

-

Appraise faster your fleet overall condition

Try the app for free

Instant Reporting

Optimizing survey reporting process for Efficient Vessel Condition Tracking

-

Streamline your reporting process by standardizing your reporting tools, and avoid wasting time compiling and structuring condition survey data with multiple softwares. We do it in seconds!

-

Quickly and easily analyze and assess your vessel's condition, enabling you to take action as needed

-

Keep track of the location and severity of any issues to prioritize repairs or maintenance effectively

-

Foster collaboration among maintenance and authority stakeholders for more efficient communication and resolution of issues

The Benefits of UTM Reporting for Fleet Asset manager & superintendent

Maximizing Fleet Maintenance Efficiency

-

Optimize maintenance schedules and reduce costs by making informed decisions based on data insights

-

Streamline coordination with all stakeholders and improve maintenance lead times, resulting in better asset utilization

-

Ensure compliance with regulations and improve safety while reducing costs

-

Easily monitor the condition and integrity of the fleet and track its development across surveys, allowing for timely interventions and preventative maintenance

Subscribe and gain a competitive edge